German industrial group Henkel and Finland’s technical research institute VTT have developed a new bio-based packaging material that could replace fossil plastics in e-commerce packaging. The joint project, conducted at VTT’s pilot facility in Jyväskylä, resulted in a market-ready cellulose foam product designed for industrial-scale use.

The collaboration marks an important step toward more sustainable packaging solutions in an industry long dominated by fossil-based materials. By using a custom-built pilot line, VTT enabled Henkel to scale its material formula from laboratory trials to full industrial production — a crucial step often referred to as the “valley of death” in innovation projects.

From fossil plastics to cellulose foam

Headquartered in Düsseldorf, Henkel is a global leader in consumer goods and industrial adhesives, employing around 47,000 people worldwide with an annual turnover of 21.6 billion euros. As part of its sustainability strategy, the company has for several years worked to reduce the use of plastic packaging and replace it with renewable and recyclable alternatives.

Cellulose foam replaces fossil plastics in Henkel’s pilot project

The goal of the collaboration with VTT was to create a lightweight, formable, and recyclable foam material made from wood fibres. VTT – Finland’s state-owned technical research centre and one of Europe’s leading institutes in biotechnology and materials science – has previously pioneered foam-forming technologies for fibre-based materials.

– Our idea was to use fibre-based foam as an alternative to fossil plastics, and we needed a research partner capable of turning that vision into reality. VTT had the equipment, expertise, and the right research focus to match our goals, said Bradley McLeod, Business Development Director at Henkel.

Pilot facility built from the ground up

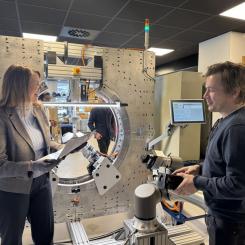

To test and produce the material at an industrial scale, VTT built a dedicated pilot line at its research centre in Jyväskylä. An entire hall was cleared for the installation — something unprecedented in VTT’s history, according to senior researcher Elina Pääkkönen.

– This project was unique. We built a completely new pilot line with full production capacity for Henkel. During the test phase, Henkel’s customers were also invited to observe the process, and one was so impressed that they decided to relocate a similar line to their own facility in the United States, Pääkkönen explained.

Throughout the project, the material’s properties were continuously tested and refined. The result was a commercially viable material that Henkel can now offer to clients for use on their own production lines.

– Thanks to VTT’s intensive work, we now have a profitable product and intellectual property that will create value for years to come. This is a milestone not only for us, but for the entire packaging industry, said McLeod.

Research collaboration with industrial impact

VTT contributed its technical expertise in cellulose foam, paper packaging, and process engineering, while also helping develop new formulations and process recommendations for industrial applications.

Henkel set ambitious performance requirements — the new material needed to match traditional plastic foams in cushioning, moldability, and durability. According to McLeod, this required several process adjustments:

– We gave VTT very demanding targets. Sometimes they said, “We’ve never done this before, but we’ll try.” And they succeeded – several times.

For VTT, the project highlights the power of combining research and industrial development. According to Jouni Lattu, Head of VTT’s packaging value chain, the partnership builds on the institute’s long-term research in fibre technology.

– The project was based on our fundamental research into fibre foam properties and scalable processing. One of VTT’s key strengths is the ability to deliver fully customised pilot projects and adapt our lines to each client’s specific needs, Lattu said.

Future packaging without plastics

Plastics still dominate the global packaging market, yet less than twelve per cent is recycled. Around 8–10 per cent of the world’s total fossil fuel production is used to manufacture plastics, and according to the UN Environment Programme, a truckload of plastic waste ends up in the oceans every minute.

With growing regulatory and consumer pressure, industries are now racing to develop circular materials that can be recycled or reused without generating harmful waste. Henkel views its collaboration with VTT as a vital step toward a more sustainable packaging future.

– For us, sustainability is not about marketing slogans but about tangible innovation. This technology makes it possible to replace fossil-based materials at scale, McLeod said.

For VTT, the project demonstrates how applied research can transform lab-scale innovations into real industrial products. The next goal is to optimise the process further and explore new applications, such as food packaging and protective cushioning materials.

If widely adopted, this new cellulose-based technology could help reduce plastic waste and strengthen Europe’s independence from fossil raw materials – while proving that sustainability and profitability can indeed go hand in hand.

Facts:

Henkel: German multinational chemical company headquartered in Düsseldorf. Founded in 1876. Operates globally in consumer goods and industrial adhesives.

VTT: Finland’s Technical Research Centre, specialising in biotechnology, materials science, and industrial innovation.

Sources: Henkel, VTT